Presentations 6th Forum Plastic Recyclates

This year's program will again cover the following thematic clusters:

Conference Day 1 (March 13, 2024)

09:30 | Registration of participants & welcome coffee

10:00 | Welcome and Introduction to the Conference | Elke Metzsch-Zilligen & Christian Beinert | Fraunhofer LBF

Dr. Elke Metzsch-Zilligen

Head of Department Additivation and Durability | Fraunhofer Institute for Structural Durability and System Reliability LBF

Dr. Metzsch-Zilligen studied chemistry at the University of Cologne and received her PhD in physical chemistry in 2006. After working in the food industry for several years, she joined the German Plastics Institute (DKI) in 2011, which was integrated into Fraunhofer LBF in 2012. She is currently head of the department "Additivation and Durability" and has been deputy head of the division "Plastics" at Fraunhofer LBF since January 1, 2024.

Her research focuses on the synthesis of new additives and the selection and evaluation of optimized additives/additive systems for thermoplastics depending on the application. She has also been working on the sustainability of plastics for many years. This includes significantly improving the quality of recyclates through adapted post-stabilization to improve the mechanical, sensory and optical properties in order to increase the amount of recyclates used or to enable the substitution of virgin material by recyclates in the first place.

Dr. Christian Beinert

Head of Department Polymer Processing and Component Design | Fraunhofer Institute for Structural Durability and System Reliability LBF

Christian Beinert studied mechanical engineering at the University of Darmstadt and received his PhD in 2007 in the field of numerical flow simulation. At the German Plastics Institute (Deutsches Kunststoff-Institut, DKI), he initially headed the research group "Compounding" and, prior to the integration into Fraunhofer LBF in 2012, the department "Thermoplastics Processing". At Fraunhofer LBF, Mr. Beinert currently heads the department "Plastics Processing and Component Design".

The department is part of the division "Plastics" at the Fraunhofer LBF and develops solutions for the resource-conserving use of plastics in technically demanding applications. It covers the entire spectrum from the determination of material properties to the simulation and development of processing methods. With a focus on the design of structural components, the department develops methods and models that can optimally and user-specifically represent material-, process- and/or application-specific influencing variables under complex load situations.

10:15 | Shaping the future: European and international standardization for plastics recycling and recyclates | Stefanie Bierwirth | DIN Deutsches Institut für Normung e. V.

Stefanie Bierwirth

Senior project manager | DIN Standards Committee Plastics (FNK)Stefanie Bierwirth studied physics at the Georg-August University in Göttingen. After completing her physics diploma, she joined the Helmholtz Center Berlin for Materials and Energy (HZB). She has been working at the German Institute for Standardization (DIN) in Berlin since 2016 and is currently responsible for standardization committees at German, European and international level for the DIN Standards Committee Plastics (FNK) in the areas of plastics recycling and recyclates, as well as environmental aspects of plastics.

10:40 | Are there enough recyclates for everyone? | Frank Stammer | TecPart – Verband Technische Kunststoff-Produkte e.V.

Frank Stammer

Specialist for circular economy | TecPart – Verband Technische Kunststoff-Produkte e.V.Frank Stammer studied economics and law at the University of Aschaffenburg, specializing in international law and finance. He then worked as a chemicals and product law specialist for various consulting firms throughout Germany until he joined TecPart - Verband Technische Kunststoffprodukte as a specialist consultant for the circular economy in 2015.

Today, Mr. Stammer is chairman of various national and European standardization committees in the field of plastics recycling as well as sustainability and recyclate application. At the same time, Mr. Stammer heads the TecPart specialist group of compounders and recyclers and advises decision-makers in political bodies in Berlin and Brussels. In addition, Mr. Stammer was recently appointed to the advisory board of the Forum Plastic Recyclates.

11:05 | Plastic recycling becoming the new normal? | Monica Harting | REMONDIS Recycling GmbH & Co. KG

Monica Harting

Public Affairs Manager / Project Management Plastics Recycling | REMONDIS Recycling GmbH & Co. KGMonica Harting studied process engineering in Hamburg. An additional MBA enabled her to further combine sustainability with economics. With her experience in the automotive industry and renewable energies, she has always focused on optimizing development processes and implementing sustainability projects. In the last 6 years she focused on recycling and worked on the optimization of the German and European waste management strategy and the development of new recycling processes.

At REMONDIS, she supports the goal of achieving a circular economy for plastics across the entire value chain and various sectors. It works together with industry associations such as PRE, PETCORE, Mehrwegverband Deutschland, BDE/FEAD or DIN/ISO. As REMONDIS has a broad portfolio of plastics recycling capacities for PET, PP, HDPE, LDPE and engineering plastics and covers all services in the waste value chain, such as collection, sorting, deposits and R&D, it is in a position to take a multilateral view of current (legislative) developments.

11:45 | Designing additive solutions enabling circular plastics | Tailor-made additives for current and future recycling streams | Jeroen Frederix & Olaf Henschke | SI Group

Jeroen Frederix

Market development manager circular economy | SI GroupPassionate about people, planet and transformation Jeroen - in his role of market development manager for SI Group – is motivated to increase the contribution of additives to a circular plastics economy. Jeroen is based out of Antwerp, Belgium. He is a chemical engineer by education with more than 15 years polymer industry experience in sales, marketing, new business development and circular economy.

Dr. Olaf Henschke

Sr. Technical Service Manager | SI Group-Switzerland GmbHDr. Olaf Henschke joined the technical and market development organization of SI Group in Switzerland as a senior technical service manager for antioxidants, specialty additives and polymer modifiers in November 2023, following a long career in the Packaging and Specialty Plastics business at Dow Europe.

He brings experience in technical service and development across many products like polyethylene, polypropylene, EPDM, polyolefin elastomers, functional polymers and some engineering plastics and their use in a number of applications including flexible and rigid packaging, automotive compounding, building and construction, wire and cable, and others. As a marketing manager he built relationships across the automotive value chain and established a strategy for functional polymers in polyamide and polyester modification but also in the growing recycling market, he worked for 7 years in the technical committee of the German industry association BKV.

Dr. Henschke has been an author in 8 patent families and many conference presentations.

12:10 | SCONA – functionalized polymers for the compatibilization of immiscible recyclates | Björn Hansen | BYK-Chemie GmbH

Björn Hansen

End-Use Specialist | BYK-Chemie GmbH1996 Apprenticeship as a chemical laboratory technician at Höchst, later Celanese, Ruhrchemie plant, Oberhausen

2005 BYK Chemie, Labor End Use Thermoplastics

2015 Technical support SEA, Middle East, Osteuropa

Topics: Recycling, modifiers & integration of (natural) fibers

12:35 | Brüggemann Stabilizers and Compatibilizers for Production of High Quality Polyolefin Recyclates | Dr. Matthias Bruch | L. Brüggemann GmbH & Co. KG

Dr. Matthias Bruch

Innovation and Product Manager Polymer Additives | L. Brüggemann GmbH & Co. KGAfter studying polymer chemistry at the University of Freiburg/Germany Dr. Dipl.-Chem. Matthias Bruch worked in the development of norbornene co-polymers in Ticona’s medical and optical applications as a head of laboratory. At TOPAS Advanced Polymers he led the development team and managed a full-continuous polyolefin production plant in Frankfurt/Germany. For the last ten years he is the product manager for the catalysts and acitvators of L. Brüggemann’s Cast Nylon products. Currently he has added other responsibilities incl. for the Bruggolen® R-Series for recycling of polyolefins and managing innovations for polymer additives at L. Brüggemann in Heilbronn/Germany.

13:00 - 14:15 | Lunch break

14:15 | A new approach to recycling: Innovative process technology for optimum quality | Felix Dreher | Coperion GmbH

Felix Dreher

Process Engineer | Coperion GmbHAfter receiving a master’s degree in process engineering from the University of Stuttgart, Felix Dreher started to work for Coperion in 2019.

In his role as a process engineer, he specialized in developing mechanical as well as chemical recycling processes of plastics using a twin-screw extruder. His main focus is on how Coperion’s technology can contribute to improve the overall process from the raw material feeding to the discharge compared to conventional systems.

14:40 | Why shall we use masterbatches based on recycled polymers for the additivation of recyclates? | Norbert Grünewald | PolyIQ GmbH

Norbert Gruenewald

Head of Business Sales and Technology | Poly-IQ GmbHNorbert Gruenewald received a Diplom Engineers Degree in chemistry and chemical engineering at Duisburg-Essen University.

He has over 50 years’ experience in sales and marketing worldwide in chemicals and polymers industry. His functional experience includes sales, marketing, strategy, developing of additives, due diligence and business management in markets which have included commodity and engineering resins, plastics conversion machinery and plastics conversion.

Since 2015 he is as Head of Business Sales and Technology at Poly-IQ GmbH in Overath, Germany responsible for developing recycled plastic waste to sophisticated products, masterbatches and special compounds based on recycled polymers, strategic studies, benchmarking and new business development.

15:05 | Advanced Mechanical Recycling Process based on the Physical Degradation and Physical Regeneration theory. Introduction of Japan national project. | Prof. S. Yao | Fukuoka University

Prof. Shigeru YAO

Specially Appointed Research Professor/Emeritus Professor | Fukuoka University

Educational Backgrounds

- 1981.3 Bc.: Department of Polymer Chemistry, Kyoto University.

- 1983.3 Mr. degree: Graduate School of Kyoto University.

- 1988.12 Dr. degree (PhD): Graduate School of Kyoto University

Professional Careers

- 1986.4 - 2007.3 Ube Industries co. ltd.

- 2007.4 - 2011.3 Mitsubishi Research Institute

- 2011.4 - 2023.3 Professor of Department of Chemical Engineering, Fukuoka University

- 2023.4 - Specially Appointed Research Professor/

Emeritus Professor of Fukuoka University

Memberships

- The Society of Polymer Science, Japan (1986-)

Fellow of the the Society of Polymer Science, Japan(2023~) - The Society of Rheology, Japan (1986-)

- Research Association For Feedstock Recycling of Plastics Japan (FSRJ) (2016~)

Chairman of FSRJ (2022~) - The Japan Society of Polymer Processing (2011~)

- ACS (2012~)

- Polymer Processing Society (2011~)

Specialty

- Polymer Physics, Rheology, Polymer Recycle, Functional Material

15:30 - 16:00 | Coffee break

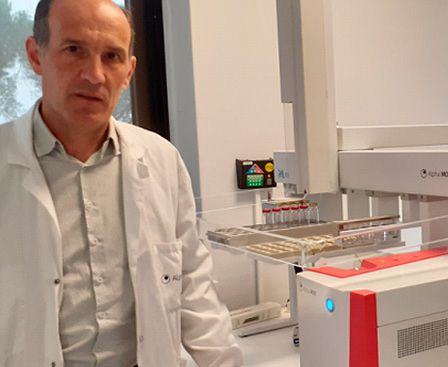

16:00 | Advanced odor-control solutions for highest quality of recycled plastics | Dr. Hervé Lechat | Alpha MOS

Dr. Hervé Lechat

Global Customer Technical Support | Alpha MOSPhD in Analytical Biochemistry at University of Nantes and INRA Nantes (France)

Expert of Alpha MOS Instruments (Heracles e-nose, Astree e-tongue and Iris e-eye and Smart Vision), application development and the technical service since 2007.

Previous experience:

ITERG Pessac (France) – 4 Years

Guyomarc’h Animal Nutrition (St Nolff, France) – analytical lab - 4 years

Alpha MOS develops, manufactures and sells innovative and leading edge sensory analysis solutions (electronic nose, tongue and eye) for industrial and consumer markets.

16:25 | Novel micron-sized marker particles with high information density for polymers | Mario Beiner | Fraunhofer IMWS

Prof. Dr. Mario Beiner

Wissenschaftlicher Leiter des Geschäftsfelds Polymeranwendungen | Fraunhofer Institute for Microstructure of Materials and Systems IMWS

Mario Beiner studied polymer physics at the Technical University of Merseburg and received his doctorate in 1995 in the field of experimental polymer physics at the Martin Luther University Halle-Wittenberg. After postdoctoral stays at the MPI for Polymer Research in Mainz and the FORTH in Heraklion, he habilitated at MLU Halle-Wittenberg in 2003 and has been a private lecturer at the Faculty of Natural Sciences II ever since. In 2012, he moved to the Fraunhofer IMWS in Halle as Scientific Director of the Polymer Applications business unit and was appointed Honorary Professor of Applied Polymer Physics at Merseburg University of Applied Sciences.

His main research topics are the relaxation behaviour and crystallization of polymers in nanoscopic domains and under the influence of interfaces and external fields. Of particular importance here are applications of highly filled rubber compounds and process-structure-property relationships in semi-crystalline thermoplastics. Typically, the implementation takes place in interdisciplinary research activities at the interface between engineering sciences, polymer chemistry and polymer physics.16:50 | How mobile NIR Spectroscopy enables an efficient recycling value chain | Adrian Vogel | trinamiX GmbH

Adrian Vogel

Business Development Manager | trinamiX GmbHAdrian Vogel is a Business Development Manager at trinamiX, a subsidiary of BASF, where he focuses on developing innovative solutions for the recycling industry.

Prior to his current position, Adrian served as Key Account Manager at BASF and as a Global Sales Manager for Bopp & Reuther Sicherheits- und Regelarmaturen GmbH.

Adrian earned his degree in industrial engineering from the University of Applied Sciences Kaiserslautern.

17:15 | Closing Day One | Elke Metzsch-Zilligen | Fraunhofer LBF

Dr. Elke Metzsch-Zilligen

Head of Department Additivation and Durability | Fraunhofer Institute for Structural Durability and System Reliability LBF

Dr. Metzsch-Zilligen studied chemistry at the University of Cologne and received her PhD in physical chemistry in 2006. After working in the food industry for several years, she joined the German Plastics Institute (DKI) in 2011, which was integrated into Fraunhofer LBF in 2012. She is currently head of the department "Additivation and Durability" and has been deputy head of the department "Plastics" at Fraunhofer LBF since January 1, 2024.

Her research focuses on the synthesis of new additives and the selection and evaluation of optimized additives/additive systems for thermoplastics depending on the application. She has also been working on the sustainability of plastics for many years. This includes significantly improving the quality of recyclates through adapted post-stabilization to improve the mechanical, sensory and optical properties in order to increase the amount of recyclates used or to enable the substitution of virgin material by recyclates in the first place.

17:45 - 19:00 | Get-together

19:00 - 21:00 | Joint conference dinner (self payer)

Conference Day 2 (March 14, 2024)

08:30 | Welcome back - Review & Preview | Christian Beinert | Fraunhofer LBF

Dr. Christian Beinert

Head of Department Polymer Processing and Component Design | Fraunhofer Institute for Structural Durability and System Reliability LBF

Christian Beinert studied mechanical engineering at the University of Darmstadt and received his PhD in 2007 in the field of numerical flow simulation. At the German Plastics Institute (Deutsches Kunststoff-Institut, DKI), he initially headed the research group "Compounding" and, prior to the integration into Fraunhofer LBF in 2012, the department "Thermoplastics Processing". At Fraunhofer LBF, Mr. Beinert currently heads the department "Plastics Processing and Component Design".

The department is part of the division "Plastics" at the Fraunhofer LBF and develops solutions for the resource-conserving use of plastics in technically demanding applications. It covers the entire spectrum from the determination of material properties to the simulation and development of processing methods. With a focus on the design of structural components, the department develops methods and models that can optimally and user-specifically represent material-, process- and/or application-specific influencing variables under complex load situations.

08:45 | Future of Plastics Recycling in Europe | Ton Emans | Plastic Recyclers Europe

Ton Emans

President of Plastics Recyclers Europe and managing Director of CeDo Group | Plastics Recyclers Europe

Ton Emans has more than 30 years’ experience in the plastic recycling process. He is Director Group Recycling.

Ton Emans started his career with DSM in Geleen, The Netherlands and worked as researcher in the field of environment and safety. In 1991, he relocated to a subsidiary of DSM called REKO, a company which started to recycle plastics in 1979. As a Quality, Environment, Safety and Health Manager he became familiar with plastic recycling. After the merger with Wavin Re-use into Arena Recycling he was named Purchasing Manager.

After the bankruptcy of Arena Recycling in 2000 Ton searched for a new owner for the site in Geleen and found CeDo willing to buy her own recycling plant. He was named Managing Director.

In 2004, Ton Emans extended his responsibilities and moved to Mönchengladbach, Germany where he was named Supply Chain Managing Director of CeDo Group.

Ton Emans holds a Master of Science in occupational health and safety from the University of Amsterdam in The Netherlands and has completed several business programs.

In 2011, Ton Emans has been named President of PRE, a non-profit organization whose members are European plastic recyclers. PRE represents National Associations and Individual companies covering 80% of the European market. PRE actively promotes the increase of plastics recycling and supports the transition towards circular economy.

9:10 | Challenges in the evaluation of plastic recyclates in a life cycle assessment | Benedikt Kauertz | ifeu gGmbH

Benedikt Kauertz

Head of the Industry and Products Department | ifeu Institut für Energie- und Umweltforschung Heidelberg gGmbH

Benedikt Kauertz is Head of the Industry and Products Department at the ifeu (Institute for Energy and Environmental Research) in Heidelberg. His work focuses on the environmental impacts of the production, distribution and disposal of packaging and the various optimisation options for reducing these impacts. Over the past 17 years, he has been involved in many national and international life cycle assessments on packaging, both for private and public sector clients in politics and civil society.

9:35 | Digitalzation as Key to a Circular Economy for Plastics | Max Meister | Cirplus GmbH

Max Meister

Founder's Associate | Cirplus GmbH

Max Meister draws from a versatile background that spans mechanical engineering, the automotive industry, musical theatre, and the circular economy.

Armed with a degree in Mechanical Engineering, Max gained extensive expertise in lean manufacturing and management. Notably, Max worked with distinguished companies such as Daimler in Germany, Mitsubishi-Fuso in Portugal, and Western Star in Oregon, USA.

Transitioning from engineering to the performing arts, Max fulfilled a lifelong dream of becoming a musical theatre performer. From rigorous training to prominent roles in productions such as Tanz der Vampire, Jesus Christ Superstar, Pretty Woman, and Die Eiskönigin, Max has demonstrated versatility as a first cast member, ensemble contributor, and swing.

In pursuit of a broader societal impact, Max redirected professional focus toward contributing to the circular economy. As a dedicated member of the dynamic team at Cirplus, Max actively works towards closing the loop for plastics, aiming to make a significant and positive impact on sustainability. Within the role of founder's associate, Max oversees collaborations with research programs, public relations, as well as event and trade fair organization. Leveraging a diverse background, Max is committed to accelerating the transition towards a more sustainable and circular future.

11:15 | Opportunities for circular design in the automotive industry | Mike Herbig | Audi AG

Mike Herbig

Technical Development, Pre-Development / Innovation | AUDI AGMike Herbig studied mechanical engineering/precision engineering in Jena for his first degree and started his professional career in Technical Development at AUDI AG in 1998.

Since 2013, he has been working exclusively on innovations as a pre-developer, intrapreneur and member of the Tech Scouting Team at AUDI AG.

Current projects are dedicated to topics of sustainability, plastic recyclates, the intrapreneurship Audi Polymer-TEAM as well as operational development scopes and strategy content of the circular economy.

This also includes cross-industry initiatives and various research and university collaborations with sustainability content.

He is currently working on his dissertation on a circular economy topic at the Technical University of Dresden. He is also a member of the doctoral network at the IKK, Leibniz Universität Hannover.11:40 | Plastics recycling in the scope of sustainability – HMG perspective | Riyaz Mohammed | Hyundai Motor Europe Technical Center GmbH

Riyaz Mohammed

Senior Engineer, Sustainability & Innovation | Hyundai Motor Europe Technical Center GmbH

- Riyaz received his master’s degree in computational mechanical engineering from RWTH Aachen university in 2018 with focus on lightweight design, simulation & material science. He has more than 7 years of experience in automotive industry with focus on plastics and their design for interior & exterior trims. He has worked with several Tier 1s & OEMs such as Volkswagen AG, Magna, Plastic Omnium and JSP.

- In his current role as a senior engineer at HMETC, he is responsible for developing sustainable materials and components with a focus on European value chain.

12:05 | Recycled nylon grades in automotive applications -Reality check- | Georgios Passas-Lagos | Pentac Polymer GmbH

Georgios Passas-Lagos

Head of Product-Management | PENTAC Polymer GmbH - Modifizierte technische KunststoffeGeorgios Passas-Lagos received his degree in Chemistry at the Technical University of Darmstadt and worked as researcher at Fraunhofer LBF. After that, he started as a product manager for polymeric materials at Kayser Automotive Systems. He was then promoted to group leader for the business unit tubing systems and polymeric materials. In that position he specialized in designing cooling line systems for electric vehicles.

Currently he is head of product management at PENTAC Polymer, responsible for all technical formulations of PENTAMID virgin and recycled grades.

12:30 - 13:30 | Lunch break

13:30 | Sustainable Material at Miele - How to Make Recycled Plastics „Immer Besser“ | Tatjana Dänzer | Miele & Cie. KG

Dr. Tatjana Dänzer

Laboratory Engineer | Miele & Cie. KGTatjana Dänzer studied Chemistry and received her PhD degree in 2019 at the Johannes-Gutenberg University in Mainz with focus on polymer chemistry. After working as a qualification engineer, she joined Miele & Cie. KG in 2021.

At the Laboratory for Rubber and Plastics, which is located in the Bielefeld plant, she assesses the applicability of plastic recyclates in white goods and other household appliances. In different pilot projects, she evaluates the possibility to generate single-grade recyclate material from the WEEE stream.

13:55 | Use of Plastic Recyclates in highly loaded technical applications – Challenges and Opportunities | Dominik Spancken | Fraunhofer LBF

Dr. Dominik Spancken

Polymer Processing and Component Design | Fraunhofer LBFAfter studying Mechanical Engineering and Polymer Technology at the University of Applied Science in Darmstadt, Dominik Spancken started working at the Fraunhofer LBF in 2011. There his fields of work are the fatigue characterization of reinforced thermoplastic Polymers and the lightweight design of structural components. In July 2020 he started his doctoral thesis in Sustainability Sciences at the University of Applied Science in Darmstadt in collaboration with the Fraunhofer LBF. The title of his doctoral thesis is “Sustainable development – the use of Polypropylene recyclates in highly loaded structural components”.

In July 2023 he graduates as the 1st Dr. rer. sust. (doktor rerum sustinentium) in Germany. Since this time he is working in several public founded projects to promote the Sustainability Transformation of new technologies and challenges.

14:20 | Future of Polycarbonate in a circular economy | Benjamin Porter | Trinseo LLC

Benjamin Porter

Global Sustainability Business Development Manager | TRINSEO LLCStudied Industrial Engineering in Hamburg.

15 year of experience in the plastic industry, with background on compounding bioplastics, technical service for Electrical & Lighting products, business development for TPU into cable applications and later also promoting Trinseo’s portfolio into the medical and personal care market.

Joined the centralized sustainability group at Trinseo ~2 years ago as a global Sustainability BDM to foster sustainability for Polycarbonate, Styrenics and compounds made therefrom.

Main focus today lies on implementation of dissolution for Polycarbonate and integrate it into our existing Stade PC asset.

14:45 | Q&A, Summary and Closing Day 2 | Elke Metzsch-Zilligen | Fraunhofer LBF

Dr. Elke Metzsch-Zilligen

Head of Department Additivation and Durability | Fraunhofer Institute for Structural Durability and System Reliability LBF

Dr. Metzsch-Zilligen studied chemistry at the University of Cologne and received her PhD in physical chemistry in 2006. After working in the food industry for several years, she joined the German Plastics Institute (DKI) in 2011, which was integrated into Fraunhofer LBF in 2012. She is currently head of the department "Additivation and Durability" and has been deputy head of the department "Plastics" at Fraunhofer LBF since January 1, 2024. Her research focuses on the synthesis of new additives and the selection and evaluation of optimized additives/additive systems for thermoplastics depending on the application. She has also been working on the sustainability of plastics for many years. This includes significantly improving the quality of recyclates through adapted post-stabilization to improve the mechanical, sensory and optical properties in order to increase the amount of recyclates used or to enable the substitution of virgin material by recyclates in the first place.

15:15 | End of conference

powered by Fraunhofer Institute for Structural Durability and System Reliability LBF

powered by Fraunhofer Institute for Structural Durability and System Reliability LBF